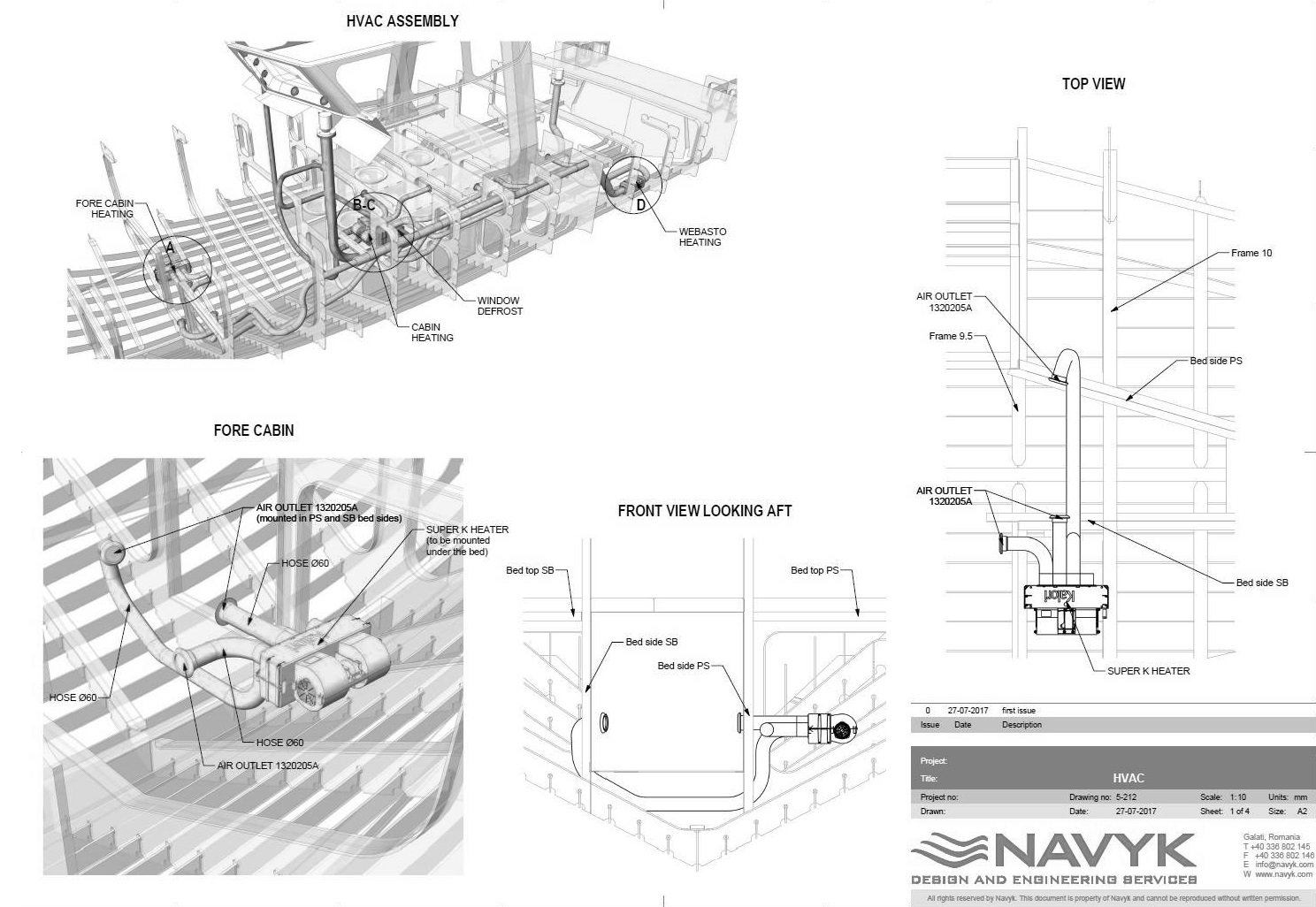

Based on the specifications of a project, we calculate the parameters and determine the necessary equipment that will form a particular system. The components and the interactions between the components will be shown within a System Diagram drawing that will capture all the essential information of the system’s design. The necessary equipment is listed in the diagrams and a general arrangement of the equipment in relation to the construction of the boat can be shown within an layout drawing.

Based on the diagrams and on the layout of the equipment, we will determine and indicate the routs through which all the rigid pipes and the flexible pipes will cross and will be mounted on board the ship, making sure that they will not interfere with the structural construction and the interior accommodations, plus we will add all the connections and the fittings. We will do this within the 3D environment. A special attention is being paid to how to access all the components of a system for service and maintenance.

The final stage will be isometric drawings of all the pipes on board, an ‘’assembly drawing’’ of the systems components.